Rhino Products has won the What Van? Aftermarket Accessories award for 2025 thanks to its latest MR4 van load area racking system. The company has invested over £2m to support MR4’s introduction, including the installation of the most up-to-date laser cutting machinery at its Deeside factory. It has also set up an operation in Nantwich dedicated to MR4, which Rhino says enables orders for the product to be dispatched rapidly.

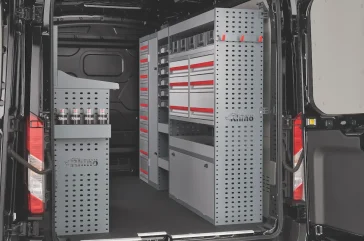

MR4 is said to be durable yet at the same time lightweight. As a consequence, its impact on the vehicle’s payload capacity and fuel consumption is minimised. Its modular design enables van owners to specify racking to meet their individual needs using Rhino’s new configurator.

Each racking unit is made to measure in order to maximise the storage potential of the cargo area and make installation quick and easy, says the firm. A bespoke fitting kit is included, and a wide variety of options are available including aluminium drawers, drop fronts, lockers and work benches.

No drilling is required to install MR4 thanks to Rhino’s no-drilling flooring partnership with Legend Fleet Solutions. Drilling is time-consuming, costly and can do damage to a van, affecting its second-hand value, Rhino points out. It can also invalidate the vehicle manufacturer’s body and paintwork warranty.

Interestingly, the no-drill approach Rhino has adopted minimises the use of adhesives and mechanical fixings, both of which can add to a vehicle’s unladen weight. The extra burden they impose is modest, but being benefits the environment.

Recognising some operators need racking fitted quickly, Rhino offers what it describes as an express MR4 range. The most-popular configurations are kept in stock and flat-packed ready for same-day dispatch.

Despite the fact that racking is used to carry parts and tools, there is no reason why it shouldn’t look stylish. Rhino has put a lot of work into MR4’s appearance, allowing its looks to complement those of the latest vans on the market.

Rhino is clearly determined to keep minimising its carbon footprint. Says a Rhino executive: “At the core of our innovation strategy is our dedication to sustainability and carbon-neutral status. We have resolved to lower the environmental impact of our products and operations.

“As part of our investment in the future the MR4 range has been designed to be future-proof,” he continues. “Its compatibility with both traditionally-powered and electric vans should ensure that it remains relevant to customers and its robust nature should ensure its longevity, making MR4 a vital part of the next generation of light commercials.”

MR4 is not the only product in Rhino’s van portfolio. Designed to transport copper pipes, plastic conduits and other lengthy items on a light commercial’s roof, the 3m-long PipeTube has recently undergone its first complete redesign since its launch in 2005. The result is PipeTube Pro.

With twin openings, the redesign encompasses an upgraded integral locking system, an added rubber seal to reduce the risk of water ingress, and an optional full-length PVC lining.

Worthy of note too is KammRack Black, Rhino’s latest van roof rack, with a new powder-coated black finish. Like its KamBar Pro and KamBar Fleet stable mates, it is shaped to allow air to flow around it with the aim of reducing wind noise and drag.

One of Rhino’s most-impressive products is SafeStow4. Featuring gas-ram-assisted lifting, it allows users to take a ladder off the roof of a van and put it back again without any need to leave the ground.

Highly Commended: Van Guard

Van Guard’s ULTILoader enables users to load and unload ladders carried on the roof of a light commercial without having to clamber up a ladder and risk falling, it went into full production in March 2024 after a prototype was demonstrated at the 2023 Commercial Vehicle Show.

Features include two gas rams and a damper for ease of use. The damper incorporates a separation piston designed to enhance safety by controlling the loading speed and minimising whipping.

Rubber wheels aid ULTILoader’s operation while replaceable rubber pads protect aluminium ladders from abrasion while reducing vibration. Dual cam-buckle straps secure the ladder in transit and ladders weighing up to 60kg can be transported (always check the maximum permitted roof loading for the vehicle concerned).